A broken scooter. A forgotten railing. A rusted gate.

Most people see waste.

The steel industry sees a second life waiting to begin.

Welcome to the reverse supply chain : the invisible journey that turns yesterday’s scrap into tomorrow’s skyline.

Chapter 1 : The Moment Steel “Dies”

It starts quietly.

- A scooter breaks down beyond repair.

- A factory upgrades machinery.

- A building is demolished.

Across India, over 120 million tonnes of steel scrap are generated every year, from vehicles, appliances, construction debris, and industrial waste. Yet to the untrained eye, this material looks finished, exhausted, obsolete.

But steel never truly dies.

Unlike many materials, steel can be recycled indefinitely without losing strength or quality.

In fact :

- 1 tonne of recycled steel saves ~1.5 tonnes of iron ore

- Saves 0.5 tonnes of coal

- Cuts CO₂ emissions by nearly 58%

- Uses 70% less energy than primary steelmaking

This is where the reverse journey begins.

Chapter 2 : Scrap Yards – The Steel Graveyards That Aren’t

The broken scooter reaches a scrap yard.

What looks like chaos is actually a system :

- Manual sorting by grade ( heavy melting scrap, light scrap, turning scrap )

- Removal of rubber, plastic, oil residues

- Cutting and shredding into furnace-ready sizes

India has over 25,000 organized and semi-organized scrap yards, employing more than 1.5 million people directly and indirectly.

This is not waste management.

This is resource recovery.

Chapter 3 : From Rust to Fire – Enter the Furnace

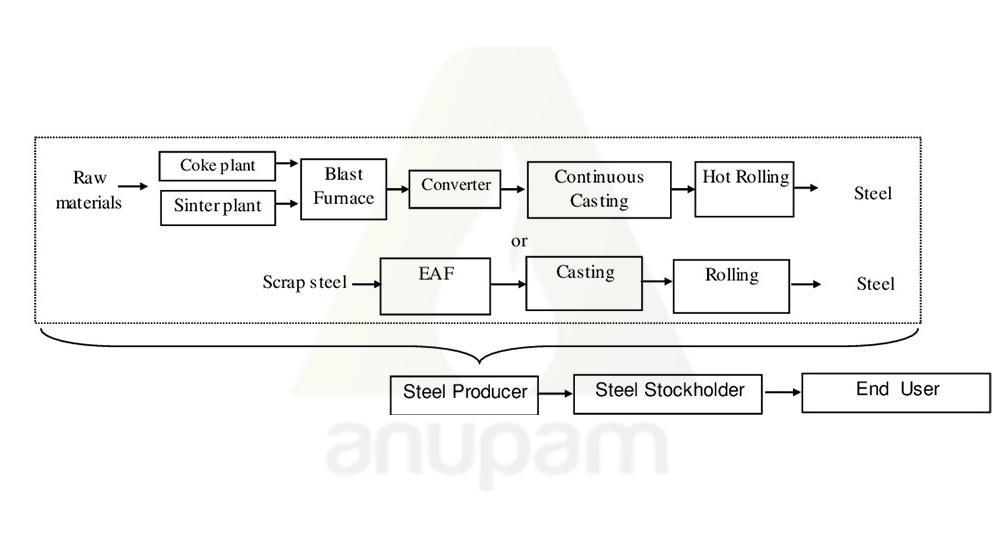

Once sorted, scrap moves to :

- Induction Furnaces (IFs)

- Electric Arc Furnaces (EAFs)

Here’s where transformation happens.

Inside furnaces operating at 1,600°C, scrap melts back into liquid steel. Chemistry is corrected using ferro-alloys, carbon, and fluxes. Impurities float out as slag.

Key numbers :

- Recycling steel uses ~2.5 MWh per tonne

- Primary steel from ore uses ~6.5 MWh per tonne

- Furnace cycles can run 24/7, producing steel every 45–60 minutes

Steel doesn’t remember what it was before.

Only what it needs to become next.

Chapter 4 : Billets – Steel’s Second Birth Certificate

Molten steel is cast into billets – long, square or rectangular bars that act as the building blocks of the steel world.

Every billet carries :

- Chemistry control

- Strength potential

- Future responsibility

A billet from recycled scrap can become :

- TMT bars

- Structural beams

- Angles, channels

- Reinforcement for homes, bridges, factories

In India alone, billet-based rolling mills supply over 60% of long steel products used in housing and infrastructure.

Your scooter’s steel is now ready to hold someone’s roof.

Chapter 5 : Rolling Mills – Where Steel Learns Its Shape

Billets enter rolling mills, passing through :

- Reheating furnaces

- Multiple rolling stands

- Quenching and tempering (for TMT)

Here, steel is stretched, compressed, shaped but never weakened.

A single billet can become:

- 20–30 meters of TMT bar

- Reinforcement for 2–3 residential columns

- Structural support designed to last 50–100 years

This is a circular economy in motion – not theory.

Chapter 6 : A New Home, A New Story

Months later.

- A new home stands.

- Children play.

- Fans spin.

- Walls hold.

Hidden inside the concrete :

- Steel reborn from scrap

- Energy saved

- Emissions avoided

- Resources respected

That scooter didn’t disappear.

It evolved.

Why the Reverse Supply Chain Matters More in 2025

- India’s Steel Demand Is Exploding

- Steel consumption projected to cross 300 million tonnes by 2030

- Urban housing, railways, highways, renewables driving growth

- Scrap Is Becoming Strategic

- India currently imports ~20 million tonnes of scrap annually

- National goal: double domestic scrap processing capacity

- Scrap-based steel = faster, cleaner, cheaper

- Carbon Pressure Is Real

- Scrap-based steel emits 1.1–1.4 tonnes CO₂/tonne

- Ore-based steel emits 2.2–2.4 tonnes CO₂/tonne

- Buyers increasingly demand low-carbon sourcing

The reverse supply chain isn’t optional anymore.

It’s a competitive advantage.

Questions People Rarely Ask ( But Should )

Q. Is recycled steel weaker?

A. No. Steel’s molecular structure allows full strength recovery when properly processed.

Q. Can scrap steel be used for critical infrastructure?

A. Yes. With proper chemistry control, scrap-based steel meets the same IS standards.

Q. Is scrap-based steel cheaper?

A. Often yes – especially when iron ore and coal prices are volatile.

Q. Does scrap reduce dependence on imports?

A. Significantly. Every recycled tonne reduces pressure on ore and coal imports.

The Bigger Picture: Steel That Respects the Future

The reverse supply chain proves one thing clearly:

Progress doesn’t always need more extraction.

Sometimes, it just needs better circulation.

In a world chasing sustainability, steel already knows the answer:

Don’t throw it away. Send it forward.

Steel Never Ends – It Simply Reinvents the Future

The next time you discard metal, remember –

It may return as a beam above someone’s head,

A bar inside a foundation,

Or strength where it’s needed most.

Steel doesn’t end.

It circulates.

And in that circulation lies the future of industry itself.