Rust is paradoxical. To a gardener it’s an enemy, to a sculptor it’s a finish. To engineers and plant managers it is a constant cost and to designers it can be a deliberate aesthetic. For industries that move, store and burn bulk materials (coal among them), rust is nowhere more consequential than on tanks, wagons, conveyor systems, railcars and storage yards.

This deep dive unpacks both problems and design language : the true scale of corrosion costs, how and why metals decay, measurable impacts on coal logistics and industrial assets, the technologies that fight it, and how smart investment in prevention saves money and carbon , over an asset’s lifetime.

The headline numbers: Corrosion at scale

- The global direct cost of corrosion is commonly cited at about US$2.5 trillion annually (roughly 3–4% of world GDP) – a macro problem with micro causes.

- In India, experts estimate corrosion drains around 2–3% of GDP annually, underscoring the national scale of the issue.

- For heavy logistics like coal, rail freight remains dominant: India carries over 1,500 million tonnes of freight by rail annually and coal makes up a substantial share, coal transport volumes are expected to grow by tens of millions of tonnes a year, putting more rolling stock and infrastructure under corrosion stress.

Put simply : Rust is not just surface-level orange, it’s a multi-billion dollar erosion of value, safety and efficiency.

What is rust ( and how does it work )?

Rust is the visible outcome of corrosion, an electrochemical process where metals (mainly iron) oxidize in the presence of moisture, oxygen and electrolytes (salts, acids). The speed of corrosion depends on :

- Environment : Marine, coastal, industrial (acidic fumes), humid vs arid.

- Material : Steel grade, alloying elements (chromium, nickel), and protective treatments.

- Mechanical stress : Micro-cracks, welding defects and fatigue accelerate local corrosion (pitting, crevice corrosion).

- Contact with contaminants : Coal dust, coal fines, chlorides/sulfates from industrial atmospheres worsen attack.

Types of corrosion relevant to coal and fuels logistics : Uniform corrosion ( general thinning ), pitting ( localized holes ), crevice corrosion ( under seals/bolted joints ), and corrosion under insulation ( CUI ) – the last is particularly stealthy and expensive.

Why rust matters to coal supply chains and fuel infrastructure

Rust affects the full value chain :

- Rolling stock & wagons : Corroded railcars are heavier (rust adds brittle deposits and leads to structural weakening), leak-prone (coal dust and fines escape), and require earlier scrap/replacement. Frequent painting and repair increase downtime.

- Conveyors & chutes : Surface roughness from corrosion raises friction losses and increases power consumption, material hang-ups and bridging increase throughput variability.

- Storage tanks & silos : Leaks, contamination and catastrophic failures (silo collapse) are risk factors if corrosion is left unchecked.

- Pipelines & valves : Internal corrosion leads to flow reduction and safety incidents, increasing operational disruption and emergency repair costs.

Because coal transport in India is overwhelmingly rail-centric and volumes are growing, more assets are exposed to corrosion stress and small corrosion rates accumulate into major replacement and safety costs.

The economics of corrosion: hard numbers and simple math

Industry reports and academic studies consistently estimate corrosion’s direct costs at 3–4% of GDP, practical estimates suggest that 15–35% of those costs are avoidable with proven corrosion management and protective technologies. That creates a huge margin for savings via preventive investment.

Example – lifecycle arithmetic for a coal hopper wagon (illustrative) :

- New wagon cost : ₹1,200,000

- Average service life without active corrosion protection : 12 years → early retirement due to corrosion at year 9.

- Annual maintenance repainting/repairs : ₹35,000/year.

- With an improved corrosion management program (coatings + cathodic measures + inspections) : Extend life to 18 years and cut annual repair cost to ₹15,000.

Simple ROI : Extra 9 years of life saved on replacement cost = ₹1,200,000 saved over life → ~₹133,333 saved per additional year. When amortized across an entire fleet of 1,000 wagons, identical savings scale to ₹133 million per extra service year making investment in coatings and inspection rapidly pay for itself.

( Actual numbers depend on material specs, local climate, inspection cadence and quality of application. )

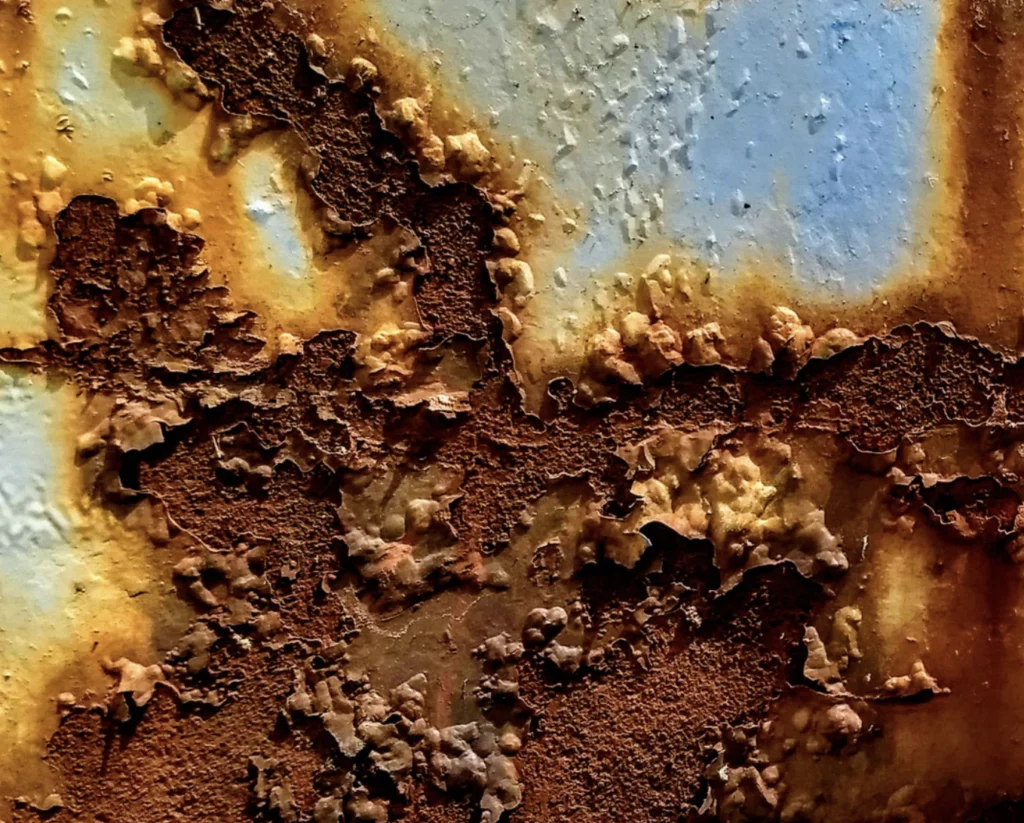

Rust as design : Patina, Corten steel and intentional corrosion

Rust isn’t always an enemy. Designers use weathering steels ( often sold under trade names like “Corten” ) to develop a stable rust patina that protects underlying metal from deeper corrosion turning decay into aesthetic and functional advantage. Key points :

- Weathering steel forms a tight, adherent oxide layer that slows further degradation in many atmospheres (not marine).

- In architecture and sculpture, controlled rust adds texture and warmth – it’s intentional aging rather than uncontrolled decay.

But beware : Weathering steels are not a one-size-fits-all solution. In aggressive chloride or constantly wet environments ( coastal, coal yards with wet coal storage ), weathering steel can fail faster than painted or stainless options.

Prevention toolbox : Coatings, cathodic protection, alloys and inhibitors

Modern corrosion control is a layered defense :

- Barrier coatings ( paints, powder coatings, epoxy primers, polyurethane finishes ) : The first and often most cost-effective line. New polymer and hybrid coatings deliver multi-year protection, studies show high-performance coatings significantly reduce corrosion rates in aggressive environments.

- Cathodic protection ( sacrificial anodes or impressed current ) : Commonly used on buried structures, pipelines and marine assets, turns the protected metal into a cathode to stop oxidation.

- Material selection & alloys : Stainless steels and weathering steels where applicable, careful selection balances cost vs long-term maintenance savings.

- Corrosion inhibitors & linings : For internal surfaces of tanks and pipelines transporting corrosive slurries or fugitive moisture.

- Design for maintainability : Avoid crevices, provide adequate drainage, specify inspection access points and isolate dissimilar metals to prevent galvanic corrosion.

Effectiveness : Peer-reviewed research and industry practice indicate combinations of coatings + cathodic protection + proactive maintenance can reduce lifecycle corrosion costs by 15–35% or more.

Inspection, detection & digital monitoring : Catching rust early

Detecting corrosion early avoids catastrophic failure. Key inspection tools and trends :

- Ultrasonic thickness gauging (UT) : Measures metal loss through thickness scanning : excellent for tanks, pipes and structural members.

- Magnetic flux leakage (MFL) : Used for pipelines and railcar wheels for internal/external defects.

- Drones + photogrammetry : Fast visual surveys of yards, stockpiles, tank farms and long conveyor runs – reduces human risk and inspection time.

- Corrosion coupons and probes : Simple electrochemical sensors to track corrosion rates in situ.

- Digital twins & predictive analytics : Combine inspection data, environmental exposure and historical rates to predict remaining life and optimize maintenance schedules.

Case insight : Institutions using predictive maintenance and digital tracking typically see reduced unplanned downtime and can plan repainting/repairs on a fiscal schedule – lowering emergency repair premiums and extending replacement cycles.

Environmental impact : Replacement steel and carbon cost of corrosion

Corrosion is not only financial – it is an environmental liability. Replacing corroded steel requires new steel production, which in turn carries embedded carbon. Research suggests the CO₂ emissions from steel used to replace corroded material could account for several percent of regional steel-sector emissions, making corrosion a contributor to lifecycle carbon budgets. In short, fighting rust is also a climate action.

Real-world corrosion scenarios in fuel & coal operations

- Coal hopper wagons : Coal fines, moisture and abrasive particles accelerate surface damage, paint abrasion from loading/unloading opens localized corrosion sites. Frequent repaint cycles and liners ( wear plates ) are common mitigation strategies.

- Storage silos & chutes : Coal dust plus moisture creates acidic microenvironments, internal coatings and regular inspection for pitting are essential.

- Coastal terminals and jetties : Chloride-laden air demands marine-grade coatings and cathodic protection, weathering steel is rarely appropriate here.

- Conveyor idlers and rollers : Corrosion increases friction and motor current draw, increasing energy consumption and maintenance frequency.

Each of these failure modes has direct economic consequences: downtime, lost throughput, fines for delayed delivery, and increased lifecycle replacement costs.

Maintenance economics : How prevention pays for itself

Three practical rules of thumb :

- Rule 1 – Spend on prevention, not just repair. A well-applied coating and inspection program can be cheaper than recurring emergency repainting and early replacement.

- Rule 2 – Target the top 20% of assets that cause 80% of failures. Focus coatings/CP and inspections on the fleet and structures that move the most material or would cause the largest disruption if they failed.

- Rule 3 – Use data to time interventions. Inspections spaced by condition rather than calendar can reduce costs and still avoid failures.

Illustrative ROI example (fleet of 500 wagons) :

- Preventive coating upgrade cost : ₹25,000/wagon (one-time) → total ₹12.5 million.

- Expected extension of repaint interval from 3 years to 8 years, replacement deferred by 6 years on average → Replacement savings and reduced downtime quickly offset the upfront cost, fleet-wide, payback periods often fall between 1.5 and 4 years depending on local conditions.

( These are model numbers – Anupam Fuels customers should run asset-specific models with real repair and downtime cost inputs to get precise ROI. )

Best-practice checklist : Keep rust from stealing value

For plant managers, logistics heads and procurement teams shipping or storing fuels :

- Audit asset exposure : Map assets by environment ( coastal, inland, humid ), age and criticality.

- Classify assets into three tiers : Critical ( immediate protections ), moderate ( scheduled protections ), low ( visual inspections ).

- Select appropriate coatings : Epoxy primers + polyurethane topcoats for outdoor coal handling, marine specs for ports. Validate via lab salt-spray and field trials.

- Implement cathodic protection where buried or submerged.

- Adopt digital inspection : Drones, UT, MFL and a central corrosion-management database.

- Train staff : Correct surface preparation and coating application are more important than the coating brand itself. Poor surface prep ruins even the best paints.

- Budget for lifecycle costs, not just purchase price. Use total cost of ownership ( TCO ) models that include maintenance, downtime and replacement.

- Consider design tweaks : Easier drainage, replace bolted crevices with welded joins where practicable, isolate dissimilar metals.

Design & aesthetic : When rust is the finish, not the failure

Urban designers and architects intentionally use oxidized finishes for warmth and texture. When done deliberately :

- Rust becomes patina, an even, stable surface that communicates age and authenticity.

- Material choice, climate and maintenance plans determine whether intentional rust will be stable or rapidly destructive.

For industrial users, marry aesthetics only when the environment is compatible ( non-marine, low-chloride ) and when structural safety is not compromised.

Corrosion control is a strategic business decision

Rust can be beautiful but in industry it’s costly. For companies such as Anupam Fuels and its customers, the question is not whether rust exists, but how much of it you budget for.

- The macro scale : Corrosion costs trillions worldwide and costs India multiple percentage points of GDP – a solvable, avoidable burden with the right technologies and planning.

- The micro scale : Smart coatings, cathodic protection, material selection and predictive inspection deliver measurable ROI – longer asset life, fewer emergency repairs and lower carbon from avoided replacements.

How Anupam Fuels helps customers fight rust

At Anupam Fuels we recognise that fuel supply reliability depends on fit-for-purpose assets. Our approach for customers includes :

- Advising on material and coating selection for wagons, silos and conveyors used in fuel handling.

- Helping model lifecycle costs so procurement decisions are made on TCO and not just upfront price.

- Recommending inspection schedules and vendor partners for application and cathodic protection installation.

- Offering logistics planning that reduces exposure (e.g., covered handling, reduced dust ingress) and therefore corrosion acceleration.