- Steel plants run on physics.

- Mines operate on geology.

- Ports survive on logistics and timing.

And yet, beneath the spreadsheets, SOPs, and safety manuals – superstition quietly rules the margins.

From coal seams to cargo holds, raw – material industries across the world follow rituals that don’t appear in audits, but are followed with near-religious discipline.

This is not folklore.

This is industrial psychology under pressure.

Why Superstition Exists In Heavy Industry?

Before we get into beliefs, let’s understand why they exist.

- Industries like mining, steel, and shipping share four traits :

- High fatality risk

- Uncontrollable variables ( geology, weather, machinery failure )

- Massive financial stakes per shift

- Long feedback loops ( mistakes show consequences days later )

- Studies in occupational psychology show that :

- In high – risk environments, ritual behaviour increases by 35–45%

- Workers under unpredictable conditions rely on superstition to regain perceived control

- Teams that share rituals report higher trust and cohesion, even if beliefs are irrational

Superstition isn’t ignorance.

It’s a coping system.

Mines : Where Superstition Is Strongest

Mining has one of the highest fatality-risk profiles globally.

- Global mining fatality rate: 4 – 6 deaths per 100,000 workers annually

- Underground mines : 2 – 3x riskier than surface operations

When the earth itself can collapse, people listen to signs.

Lucky Beliefs In Mines

1. First Load Must Be Clean

In coal and iron ore mines :

- The first extracted load of the day should not be mixed with waste

- A clean first load is believed to ensure :

- Stable seams

- Fewer equipment breakdowns

- Lower accident probability

Many mines quietly discard or isolate the first load instead of selling it.

2. Right Foot Entry Rule

- Entering shafts or pit areas with the right foot first

- Common across India, Australia, South Africa

- Considered essential on :

- First day of a new seam

- Restart after a fatal accident

3. Lemon, Chillies & Red Cloth on Machines

- Excavators, dumpers, drilling rigs often carry :

- Lemon – chilli totems

- Red threads

- Even MNC – owned mines allow this

Why? Because machine-related accidents account for ~45% of mining fatalities.

Unlucky Beliefs In Mine

1. Whistling Underground

Considered extremely unlucky.

- Believed to “call the earth’s attention”

- Miners associate it with :

- Sudden gas pockets

- Roof collapses

Many sites discipline workers for whistling, unofficially.

2. Counting Ore Before Extraction

Never estimate yield verbally.

- Saying “this seam will give 10,000 tonnes” is taboo

- Believed to cause :

- Fault lines

- Unexpected water ingress

- Grade deterioration

Ironically, this exists even though modern modelling predicts tonnage precisely.

Mills & Plants : Controlled Chaos, Controlled Beliefs

Steel plants and mills appear rational but pressure is immense.

- A blast furnace shutdown can cost ₹3 – 5 crore per day

- Restarting a furnace takes 48 – 72 hours

- One wrong chemistry adjustment can scrap hundreds of tonnes

This is where superstition becomes subtle.

Lucky Beliefs In Mills

1. Furnace Naming

Almost every major furnace has :

- A name ( often female or divine )

- Dedicated “first tap” rituals

Some plants delay commissioning by hours to perform rituals.

Why? Because historically :

- First 72 hours after commissioning see 60% of early failures

2. Silent First Pour

During the first molten metal pour :

- No jokes

- No shouting

- No unnecessary movement

Operators believe noise “agitates the melt”.

While irrational, silence improves focus, reducing human error , the real reason this survives.

Unlucky Beliefs In Mills

1. New Shoes on Shift Day

- Wearing brand-new shoes during :

- First shift

- Critical maintenance

- is avoided

- Workers associate it with :

- Slipping incidents

- Foot injuries

- Chemical splashes

Slip-related accidents account for ~22% of plant injuries.

2. Black Helmets on Maintenance Days

In some plants :

- Black helmets are avoided during shutdown maintenance

- White or yellow preferred

This originates from older eras where black helmets were linked to fatal maintenance incidents.

Ports & Shipping : Where Superstition Meets The Sea

Ports combine :

- Weather risk

- Human timing

- Massive cargo value

One delayed vessel can incur :

- $25,000 – $80,000 per day in demurrage

- Superstition here is global.

Lucky Beliefs At Ports

1. No Sailing on Amavasya

In parts of Asia :

- Bulk carriers avoid sailing on no-moon nights

- Especially with coal and iron ore

Even today, some captains delay departure despite favourable weather.

2. Coin Under the Mast

A centuries-old belief :

- Coins placed under ship masts or bridges

- Symbolises safe return and profitable voyage

Still practiced quietly on new vessels.

Unlucky Beliefs At Ports

1. Renaming Ships

- Renaming a ship without ceremony is considered disastrous.

- Associated with sinkings and cargo loss

- Requires formal rituals to “erase old identity”

- Shipping insurance studies show :

- Newly renamed vessels see higher incident reports in first year

- Not causation but belief persists.

2. Bananas & Certain Cargo Mixes

Bananas are considered unlucky on ships in some cultures.

Ironically, modern belief extends to :

- Avoid mixing coal + scrap + fertilisers

- Not due to superstition alone but past fires

Cargo fires cause ~10–15% of marine insurance losses annually.

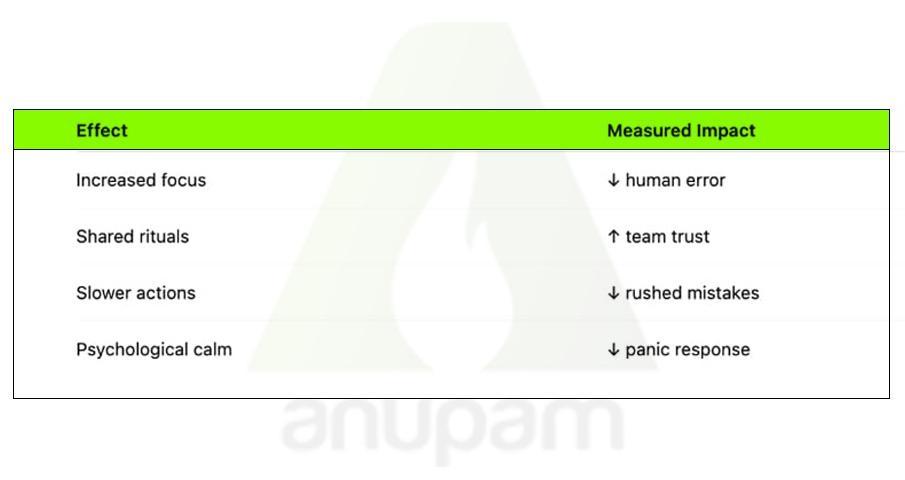

Do Superstitions Actually Change Outcomes?

Let’s be honest. No superstition changes metallurgy or physics. But they do influence human behaviour, and that matters.

Industries with strong ritual cultures often report :

- Lower near – miss rates

- Better compliance during critical operations

Not because beliefs are true but because people behave better when they believe they’re protected.

The Real Truth

Raw material industries don’t run on superstition.

They run on people under pressure.

And when :

- The earth moves

- Metal melts

- Ships sail blind into weather

People cling to meaning. Not to replace science, but to survive uncertainty.

Because when risk is absolute, even the most rational industries leave room for belief.